Trade blades in African swords

October 8, 2023

Most collectors are well aware that European blades can and do appear in African swords. However it is still often difficult for some, particularly those with an interest and experience with 18-19th century military swords, to reconcile the crude nature and style of many trade blades with the sophisticated blade production centers of Europe. Why were so many simple, roughly finished triple and single fuller broadsword blades still being made?

For a start we know some of the manufacturers. Makers like Clauberg and Peter Kull, both of Solingen, produced single and triple fuller blades in the 19th century for export. Both these makers made fine sabers, presentation swords and other items for European states and clients. But they evidently also made large numbers of these basic swords as well for export. Many ended up in major Sahel centers like Kano, in modern day Nigeria.

To understand something of the economic reasons behind this, it is necessary to briefly describe the processes involved in making swords at the time. For several centuries water powered trip hammers and grind wheels had been used by blade maker's workshops. This semi industrialized process allowed for uniformity in the final product. In parallel steel production techniques had improved in quality and consistency. By the 17th munitions grade swords were being produced relatively cheaply. Swords like the schiavona featured heavy broadsword blades of often simple design and levels of finish. These products would also form the base of cheap exports to the African continent and the design traditions that would carry on into the 19th century.

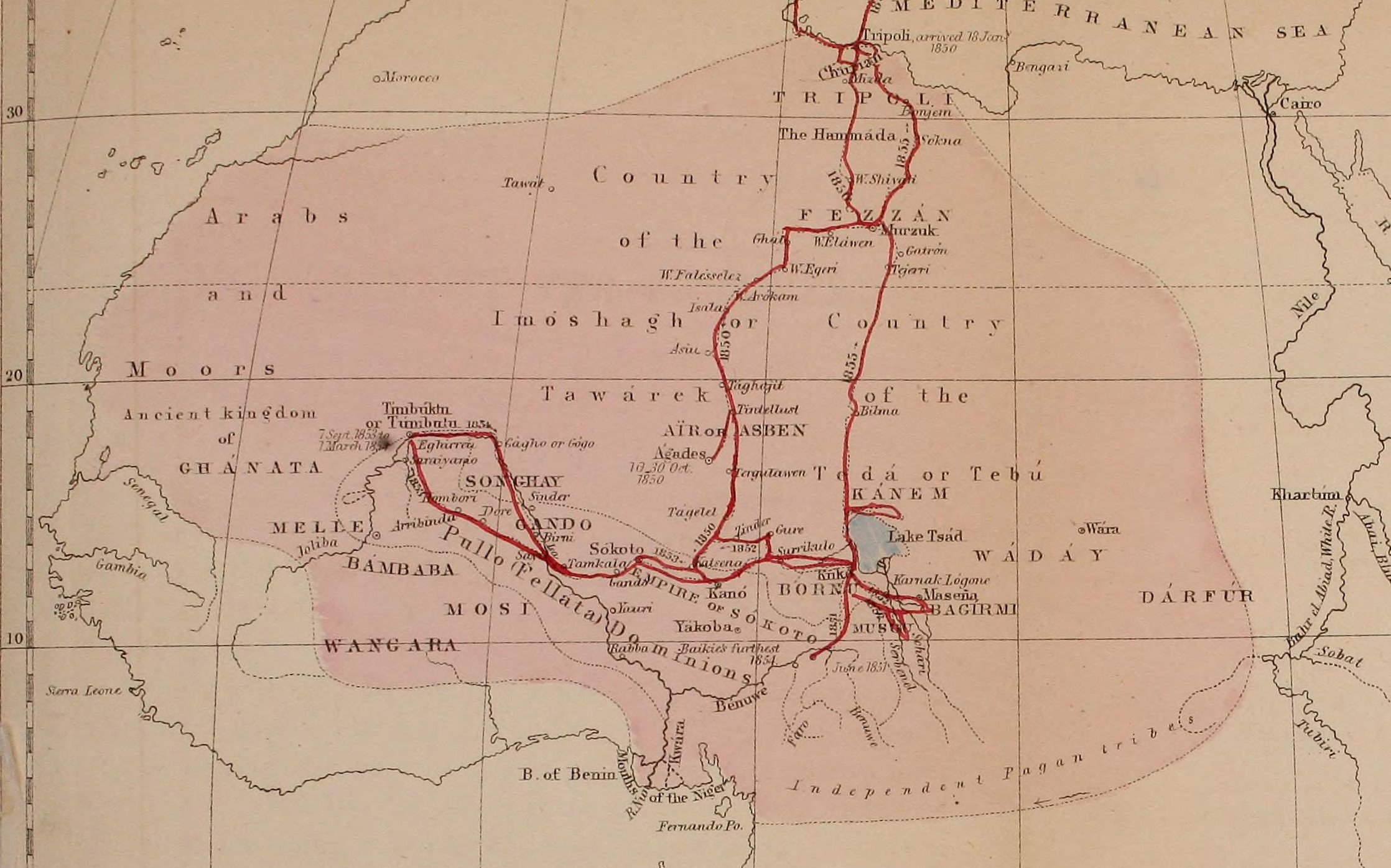

These blades so often encountered in 19th century African swords are not some bizarre aberration but rather part of a long and continuous tradition. Bypassing the time consuming polishing and levels of finish required for a contemporary sword destined for a European client, like an officer's saber, production costs were kept low. This is evidenced in full by the relative prices demanded in Africa. Heinrich Barth records in Kano the price of an unset sword blade as 1000 cowrie shells (the local form of currency). In comparison a bull could cost 8,000. Clearly there was a great abundance of cheap European produced blades, almost exclusively from Solingen in the mid 19th century. Barth also usefully records the fluctuation in sword blade prices. In Tuareg areas around Timbuktu that price could be equivalent of roughly 10-12,000 cowries.

This does not mean European blades were excessively cheap by local standards, but they were good value. Many surviving swords show extensive use.

As Barth rightly notes, there was a good profit from the importation and resale of sword blades from major centers like Kano.

Barth's travels in the Sahel

If the blades could be sold for a profit in Africa, then there was clearly an economic reason that kept Solingen makers producing them. Part of the reason for this was the poor quality in iron ore around Kano and other Sahel centers. While some regions, particularly Mandara, had very good ore, many did not and a locally produced sword would be quite inferior to the European steel of the time.

In summary there is nothing strange about finding so many European blades in Africa and certainly nothing strange about the style and the types produced into the mid 19th century in Europe for these markets. The economic factors on both sides are quite clear. While the contrast with what Solingen makers were producing with other regions is quite large, the needs and reasons behind both are sharply defined and pose no contradiction.